Description

Proton is used to remove calcium, corrosion and other inorganic contaminants. It is generally used as a final polishing step for dairy, brewery winemaking and food plant CIP operations.

In food plant cleaning operations, it should be used after all heat-exchange equipment has been cleaned with a suitable caustic cleaning agent, such as our Singlex or Sledge.

For economical and consistent results, Proton should be dosed automatically via conductivity or flowmeter control methods.

Product Features:

- Blended acid

- Contains surfactants

- Less corrosive

- Removes residual oils

- Quick-rinsing

- Made in accordance with HACCP and GMP guidelines

- Suitable for use in all Australian food manufacturing plants

Attention: Brewery Operators

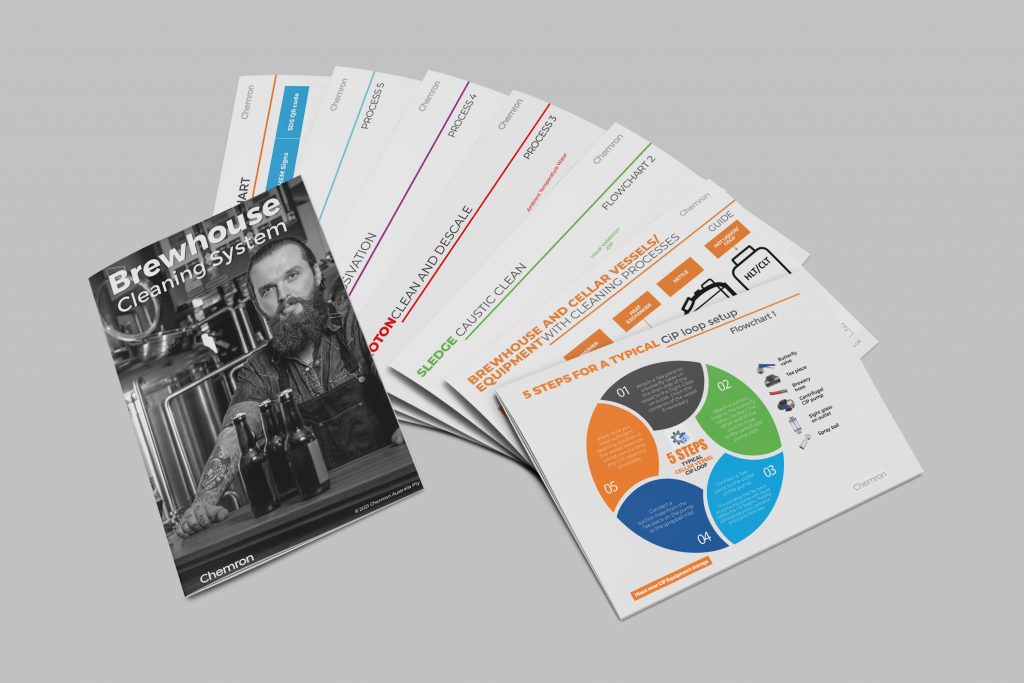

We have developed a detailed, step-by-step cleaning and sanitising system which includes an illustrated manual, wall-mountable diagrams and material storage safety signs.

This system was developed in conjunction with two brewery system consulting firms, a supplier of CIP cleaning equipment and several brewers from large and smaller breweries.

If you would like us to send you a kit please contact us via the form below, or by calling us on 1800 812 309.

Proton is a highly effective replacement for Nitric 45.

If you have any questions about using Proton as a replacement for Nitric 45 please call us or fill in the form below.

Reviews

There are no reviews yet